Why Choose Us?

Conservative design leads to enhanced reliability and longevity

Our philosophy starts with a safe, conservative design and quality components to minimize unscheduled down time and extend the economic life of the equipment.

In our case, a conservative design means that all of the components are operated well below the component manufacturer’s recommended maximum operating conditions.

Our “severe duty” design is for applications requiring operation for at least 20 hour per week. This design operates the pump at no more than 75% of the rated speed. Our most popular severe duty design operates the pump at 67% of the rated speed and 83% of the rated pressure.

The industry rule of thumb is that when this type of pump is operated at 50% of the rated pressure the life of the pump is doubled and when operated at 50% of the rated speed, the life of the pump is quadrupled. In our severe duty line, we expect the design at least doubles the life of the pump.

In the applications where the equipment is exposed to a marine environment, the frame is sandblasted, primed and multiple coated in accordance with generally accepted marine coating systems. The hardware is 316 stainless steel as is many of the components. Where needed we provide 316 stainless steel pumps and other components.

Niagara Pressure Washers, Steam Cleaners, Hydrostatic Test Equipment and custom designed Pump Packages by Acme Cleaning Equipment, Inc. should be considered when the task is critical, duty hours are long, the environment is harsh or hazardous, and long equipment life is required.

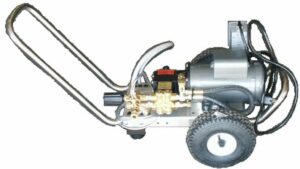

Standard Power Washer Features

- Strainer: heavy-duty cast bronze.

- Thermal relief valve designed to prevent overheating of the pump.

- Unloader bypass valve, the primary pressure relief valve.

- Safety pressure relief valve is a redundant safety back up for the unloader valve.

- Chemical injectors are typically the downstream type where the chemical injector is located after the pump and in heated units, after the heater.

- Hoses sized for minimal pressure loss and a 4:1 safety.

- Spray gun assemblies typically consist of a trigger gun, lance, twin nozzle holder with high-pressure narrow fan nozzle and low-pressure chemical application nozzle.

- Frame heavy duty constructed of structural steel.

- Corrosion protection, the standard is two party high build epoxy and an option is a standard marine multi step coating. All nuts and bolts are 316 stainless steel.

Our History

Founded in 1970 - Over 55 Years of Satisfied Customers

- On July 6, 1970, Fred B. Machol, John C. Prisel, and Charles D. Marshall were issued a Certificate of Incorporation for Acme Cleaning Equipment, Inc. by the State of Texas, Charter No. 277779.

- The corporation was organized to engage in the business of purchasing, manufacturing, refining, distributing, selling, and trading in and with any all cleaning equipment and supplies.

- The post office address of its initial registered office was 1300 Fifth Street, P.O. Box 102, Seabrook, Texas. The physical address was 1209 Highway 146, Seabrook, Texas 77586.

The first order received was repair parts for a large pump in Mexico. Advertising was limited to the Thomas Register of Manufacturers, Yellow pages, magazines, and trade shows. Sales were mostly to equipment rental stores and private label pump and washdown systems. Fred did most of the selling and John handled purchasing and administration while Charles did the books and in the evenings they all participated in assembling the equipment.

Shaping ACME Cleaning Equipment into What it is Today

- As the sales increased and more people were needed in assembling the equipment, they hired high school kids to work part-time after school. Today some 50 years later, two of those high school boys (brothers, one since 1975 and the other since 1978) are essential employees at Acme.

- Customer and vendor relationships were forged in the 1970s that continue today our customer base expanded to Agriculture (pumps and equipment for spraying fertilizer and pesticides), ranching (wash down equipment for trailers, barns, and stockyards), heavy manufacturing (pump systems that were part of the process as well as washdown of equipment for maintenance), industrial cleaning chemicals and janitorial supplies.

- In 1985 Robert O. Berry, Jr. “Buddy” joined the sales force to bring in oilfield customers. His experience as a sales engineer in the electrical, lighting, and pump package areas made a good fit with Acme’s plans. Shortly he was promoted into management, started acquiring stock and by 2001 he became the sole stockholder.

- In 2024 Robert O. Berry, III joined as VP of Sales and Marketing. Robert has over 30 years of experience in the Oil & Gas industry in roles ranging from Sales Engineer to President.

- We purchased our current location (6839 Piccadilly Drive Houston, Texas 77061) in 1991.

Capability Statement

Robert Berry, r.berry@ace-n.com, 713-643-4343, https://AcmeCleaningEquipment.com

Acme Cleaning Equipment, Inc. manufactures Niagara industrial duty pressure washers, steam cleaners, high pressure pump systems and high pressure washdown equipment with wide range of configurations such as single or multiple users which can be driven by motors (electric, hydraulic or air; fixed or variable speed) or engines (diesel or gasoline) with heaters which use gas (natural, propane, butane), diesel, electric as well as steam heat exchanger. These can be configured on heavy duty compact bases or caged frames on oilfield type skids with forklift slots and lift eyes. Where needed we also provide custom designed equipment.

This cleaning equipment is designed for long duty hours in harsh environments used in industries such as offshore oil and gas drilling, land drilling, refineries, chemical plants, sewer cleaners, marine, shipyards, pharmaceutical manufacturing, military, vehicle maintenance, packing, processing and other heavy industries.

Replacement triplex plunger pumps for hydraulic systems, BOP, reverse osmoses, fire systems, seawater, brine, 316 stainless steel, high temperature boiler feed, high temperature and high pressure, CO2 , machine tool, Bentonite, Pentane. Accessories such as hoses, shut off guns, pressure regulators, unloaders, rotating nozzles, sewer cleaning nozzles, chemical injectors and more.

| Past Performance | Differentiator | |

| 2024 OneN4X, 2 gun, auto opeation, 8.6 gpm at 3000 psi, $30,607USD and 2023 One XP, auto 3000 psi $26,075USD | Saudi Arabia Oil & Gas, The reliability and low operating cost of the 2023 unit led to the purchase of the 2024 unit. | |

| Explosion proof pressure washers 2019-2023 35 units $437,442USD 2024 27 units $383,082USD | UAE Oil & Gas customer since 2016 , proven reliability, low maintenance and lowest owning and operating cost. | |

| Explosion proof pressure washers 2019-2023 11 units $171,235USD 2024 7 units $128,525USD | UAE Oil & Gas customer since 1998 , proven reliability, low maintenance and lowest owning and operating cost. | |

| High pressure test equipment since 1989. 2019-2023 13 units $555,400USD | US Oil tool Manufacturer collaborated on design and upgrades. | |

| Customer since 1985 Explosion proof pressure washers 8 gpm 2700 psi 2019-2023 27 units $403,359USD | Egyptian Oil & Gas Drilling Company proven reliability, low maintenance and lowest owning and operating cost. | |

| Company Data | Codes and Data | |

| Est. 1970 to manufacture pump systems variable frequency drives, electric motors positive displacement pumps, saltwater, brine, 316 stainless steel, high temperature, CO2, machine tool, bentonite, pentane. Custom designed pump systems. Pumps and accessories. | UIE EAMCXM9NCNH9 DUNS 051878932 CAGE Code 1KJC7 NAICS 333914, 333996, 423830, 423850 PSC 4320 NIGP Accept credit and purchase cards | |