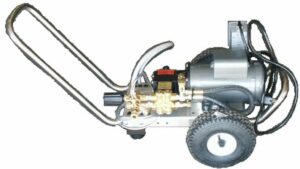

Custom Industrial Pressure Washers

ACME Custom Designed Power Washers and Pump Packages for Hazardous or Non-Hazardous areas

Acme Cleaning Equipment, Inc. is pleased to offer our customers the benefits of having a cleaning system that best fits their needs at a price that is price competitive with assembly line produced equipment. Our industrial pressure washers are built with the highest quality components based on your application and environment.

Things to Consider when Choosing Equipment

Type of Cleaning

- What pressure and flow rate will provide the most efficient results? We consider the pressure to be more of a cutting action where the flow rate provides more of a pushing action. Typical examples are a coin-operated car wash usually is about 4 gpm at 1000 psi; where a truck wash is more like 5 gpm at 1500 psi and concrete cleaning 5 to 6 gpm at 2500 to 3000 psi. Is some type of automation required?

Duty Cycle

- How often and how long are the cleaning tasks to be performed? The longer the cleaning and more often the task is performed, the more durable the components need to be.

Controls

- If the cleaning task is performed by one operator at a time and the equipment is located close to the task then the on/off controls can be mounted on the equipment. However, if there are more than one operator, in multiple locations then the controls need to be mounted at the task. In many cases it is more efficient for the equipment to be provided with what we call “Automatic Operation” where the actuating of the spray wand starts and stops the equipment.

Environment

- If the equipment is located in a marine environment, an environment in which there could be hazardous gasses or one where the ambient temperature is unusually high or low; considerations on which components would be best need to be made.

Size or Location Limitations

- Are there size or portability considerations? Does the equipment need to be wall mounted; need a roll cage type of protection; length, width or height limitations or need to be mounted in a location remote from the task?

Custom Pressure Cleaning Solutions

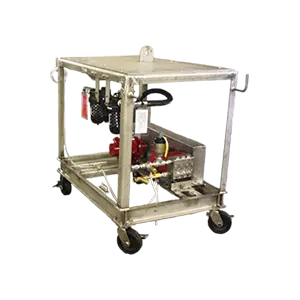

Custom Pressure Washing Application for the Oil & Gas Industry

Problem

A client of ours was experiencing problems finding industrial cleaning equipment for an offshore drilling rig. This particular client required an explosion-proof pressure washer for use in a splash zone.

Solution

Our team at ACME Cleaning Equipment suited our client with an air motor-driven pump with 316SS construction mounted in a heavy-duty, 316 Stainless Steel cage providing about 4 GPM at 3000 psi.

Results

The customer was so pleased with the results seen from this equipment that they went on to purchase several more for their other rigs.

Custom Pressure Washing Application for the Automotive Industry

Problem

Specifications from this automobile manufacturer required a portable electric washdown unit with variable flow 0-4 GPM, variable pressure 0-3000 psi, and variable temperature from ambient to steam.

Solution

Our team at ACME Cleaning Equipment suited our client with an air motor-driven pump with 316SS construction mounted in a heavy-duty, 316 Stainless Steel cage providing about 4 GPM at 3000 psi.

Results

The customer was so pleased with the results seen from this equipment that they went on to purchase several more for their other rigs.

Standard Power Washer Features

- Strainer: heavy-duty cast bronze.

- Thermal relief valve designed to prevent overheating of the pump.

- Unloader bypass valve, the primary pressure relief valve.

- Safety pressure relief valve is a redundant safety back up for the unloader valve.

- Chemical injectors are typically the downstream type where the chemical injector is located after the pump and in heated units, after the heater.

- Hoses sized for minimal pressure loss and a 4:1 safety.

- Spray gun assemblies typically consist of a trigger gun, lance, twin nozzle holder with high-pressure narrow fan nozzle and low-pressure chemical application nozzle.

- Frame heavy duty constructed of structural steel.

- Corrosion protection, the standard is two party high build epoxy and an option is a standard marine multi step coating. All nuts and bolts are 316 stainless steel.