Offshore Drilling Company Needing Pressure Washers that Work

Background

A recently promoted VP for a drilling company visited his 30+ offshore rigs and was not happy about their cleanliness. Over and over again when he asked why he was directed to a pile of discarded pressure washers and basically told “…we don’t have the right tool for the task”.

The Requirements

Engineering and Procurement were given the task to design and procure equipment that would meet the following criteria:

- No unscheduled down-time

- Easy to operate.

- High-pressure hot water.

- Long duty life.

- Have this equipment in place on all rigs within the next 12 months

Procurement & Engineering's Course of Action

- Search for a vendor that could design and deliver.

- In December the decision was to go with Acme Cleaning Equipment.

- Engineering and Acme completed the design early January.

- Procurement issued the first orders in late January.

- Delivery of the first pressure washer was the following April and the 31st power washer was delivered in January.

The Solution

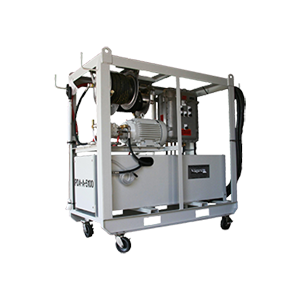

- Engineering had already decided they wanted the pump to be the high-pressure centrifugal pump by Rotojet and to have two for 100% redundancy.

- This required two 72 kW electric heaters which were plumbed so that any combination of pump and heater could be in operation while the other pump or heater could be maintained or removed from the system while in 100% operation.

- The heaters were downstream from the pumps so that only cold water went through the pumps which extended the life of the seals.

- Heater design was a coil of pipe for the high-pressure water flow mounted in a tank of water with the electric heater. The significance of this design is the process water was isolated from the heat transfer fluid (water). Therefore the heater elements did not accumulate a coating of minerals, which is the primary cause of heater failure (redundant safeties to assure the elements were submerged prior to energizing).

- The design incorporated an alternator to automatically switch from pump 1 to pump 2 when the pumps were activated.

- When the system was in “Auto” (Hand-Off-Auto switch) the heaters would maintain heat in the tanks so that hot water was always available almost instantly.

- Controls started and stopped the motors on demand.

- The equipment was connected to a pipe system which ran through the rig with outlets at convenient locations. Each outlet had a ball valve, hose and spray wand.

- The operator would turn on the ball valve and get to work. When finished, the system would shut down.

- The customer put this equipment on two new builds in a Singapore shipyard, that shipyard made some changes and the system became their standard for the next several years.

Industrial Duty and Continuous Duty pumps are also available.