Why Choose Us?

Conservative design leads to enhanced reliability and longevity

Our philosophy starts with a safe, conservative design and quality components to minimize unscheduled down time and extend the economic life of the equipment.

In our case, a conservative design means that all of the components are operated well below the component manufacturer’s recommended maximum operating conditions.

Our “severe duty” design is for applications requiring operation for at least 20 hour per week. This design operates the pump at no more than 75% of the rated speed. Our most popular severe duty design operates the pump at 67% of the rated speed and 83% of the rated pressure.

The industry rule of thumb is that when this type of pump is operated at 50% of the rated pressure the life of the pump is doubled and when operated at 50% of the rated speed, the life of the pump is quadrupled. In our severe duty line, we expect the design at least doubles the life of the pump.

In the applications where the equipment is exposed to a marine environment, the frame is sandblasted, primed and multiple coated in accordance with generally accepted marine coating systems. The hardware is 316 stainless steel as is many of the components. Where needed we provide 316 stainless steel pumps and other components.

Niagara Pressure Washers, Steam Cleaners, Hydrostatic Test Equipment and custom designed Pump Packages by Acme Cleaning Equipment, Inc. should be considered when the task is critical, duty hours are long, the environment is harsh or hazardous, and long equipment life is required.

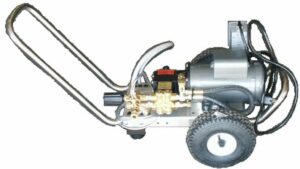

Standard Power Washer Features

- Strainer: heavy-duty cast bronze.

- Thermal relief valve designed to prevent overheating of the pump.

- Unloader bypass valve, the primary pressure relief valve.

- Safety pressure relief valve is a redundant safety back up for the unloader valve.

- Chemical injectors are typically the downstream type where the chemical injector is located after the pump and in heated units, after the heater.

- Hoses sized for minimal pressure loss and a 4:1 safety.

- Spray gun assemblies typically consist of a trigger gun, lance, twin nozzle holder with high-pressure narrow fan nozzle and low-pressure chemical application nozzle.

- Frame heavy duty constructed of structural steel.

- Corrosion protection, the standard is two party high build epoxy and an option is a standard marine multi step coating. All nuts and bolts are 316 stainless steel.